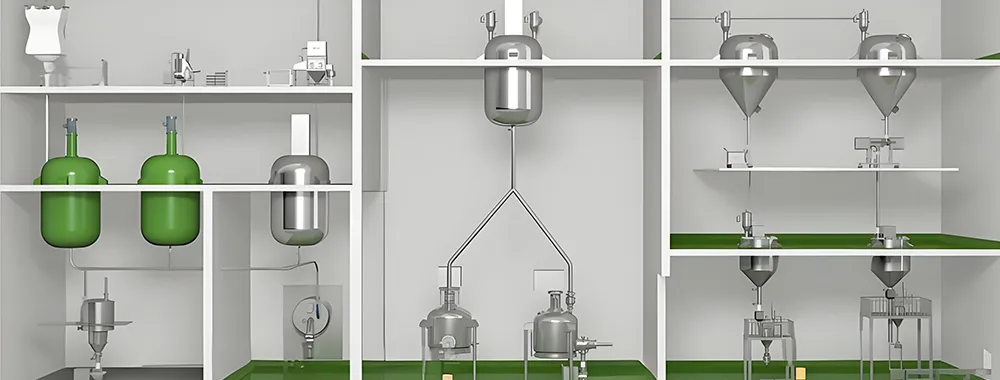

Powder Handling & Processing Equipment and Systems

Size Reduction & Milling Equipment

Particle size reduction equipment for milling of powders and granules

-

- Hammer Mill The hammer mill is designed for efficient size reduction of powders and granules. Material is evenly fed into the milling chamber through a rotary valve, where high-speed rotating blades apply impact and shear forces to achieve fine and uniform particles with a milling precision of up to 200 mesh.

- Processing capacity

600–1000kg/h - Power

7.5kW

- Processing capacity

-

- Oscillating Granulator Designed for both dry and wet material milling, the oscillating granulator is particularly suitable for temperature-sensitive or difficult-to-process materials.

- Voltage

3 phase, 380V, 50Hz - Rotor speed

27–155rpm - Power

2.2kW - Net weight (without base)

320kg

- Voltage

-

- Conical Mill The conical mill is designed for milling wet materials in pharmaceutical, food, and chemical industries.

- Voltage

3 phase, 380V, 50Hz - Rotor speed

500–1500rpm - Power

5.5kW - Net weight (without base)

320kg

- Voltage

Solutions for Industries

What types of materials are suitable for the hammer mill?

What types of materials are suitable for the hammer mill?

The hammer mill is ideal for milling dry, brittle, and crystalline materials such as active pharmaceutical ingredients (APIs), food additives, dyes and pigments, and herbal materials. Once fed into the chamber, materials are rapidly reduced under the impact of high-speed rotating hammers, resulting in fine and uniform output.

How does the CFJ hammer mill differ from standard hammer mills?

How does the CFJ hammer mill differ from standard hammer mills?

The CFJ hammer mill features a more precise structure and a superior hygienic design. It operates on a combined high-speed shearing and centrifugal impact principle, producing finer, more consistent particles. The system is easy to dismantle for cleaning and fully compliant with GMP standards.

What types of materials is this mill suitable for?

What types of materials is this mill suitable for?

The oscillating granulator is highly versatile, suitable for milling pharmaceutical APIs, excipients, herbal extracts, food additives, seasoning powders, and chemical raw materials. It is particularly well-suited for industries with strict requirements on particle size and cleanliness.

What is the typical production capacity? Can it support continuous operation?

What is the typical production capacity? Can it support continuous operation?

The oscillating granulator supports both batch and continuous production, with a processing capacity ranging from 300kg/h to 1500kg/h. It is ideal for laboratory use, pilot-scale production, and full-scale industrial applications.

Which model is recommended for wet material milling requiring uniform particle size distribution?

Which model is recommended for wet material milling requiring uniform particle size distribution?

The conical mill is an ideal choice. It is designed for pharmaceutical, food, and chemical applications requiring wet granulation or particle size reduction. It delivers uniform particle distribution and excellent flow properties, making it especially effective for milling before or after granulation and drying.

What are the advantages of this mill compared with traditional hammer or high-speed mills?

What are the advantages of this mill compared with traditional hammer or high-speed mills?

Unlike traditional hammer mills, the conical mill operates with a gentle and uniform milling motion that minimizes heat generation and excessive fines. It produces granules with better flowability and narrower size distribution, ideal for heat-sensitive, cohesive, or re-granulated materials.