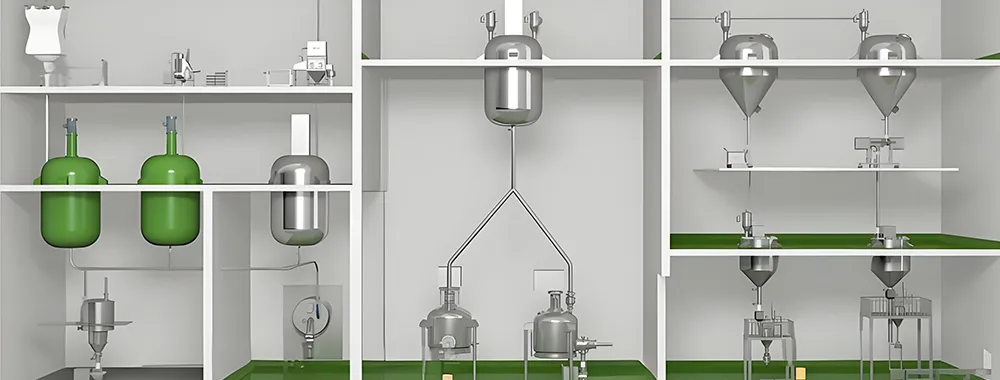

Powder Handling & Processing Equipment and Systems

Weighing and Dispensing Containment Isolator (WDCI)

Containment isolator system for weighing, filling and dispensing of highly potent compounds under ultra-clean conditions

- Moisture content: ≤1ppm

- Oxygen content: ≤1ppm

- Filling range: 1–25kg

- Accuracy: ±5g (for filling ≤10kg)

±10g (for filling ≤25kg) - Production capacity: 2500kg/h

Features

- Ultra-clean and airtight containment

The isolator maintains a constant internal pressure of 3–5 mbar and an oxygen/moisture concentration ≤1 ppm to ensure complete isolation of sensitive materials such as lithium battery compounds or pharmaceutical actives. The integrated gas purification and circulation system maintains a stable inert atmosphere (e.g., nitrogen), effectively preventing contamination or degradation. - Continuous and efficient operation

Designed for uninterrupted production, the system includes a dedicated inlet buffer and empty bottle storage chamber, enabling multiple container changes without downtime. Automatic bottle replenishment maintains workflow continuity, while filled containers are transferred directly to the next stage without disrupting the controlled atmosphere. - Precision filling and sealing

Equipped with a vertical auger filler driven by a servo motor and closed-loop control, it ensures high-precision filling of ±5 g for loads ≤10kg and ±10 g for loads ≤25kg. The inflatable sealing door creates a reliable airtight seal within seconds and releases easily for safe operation and zero leakage. - Enhanced safety and automation

The system provides complete operator isolation to prevent exposure to high-potency or toxic compounds such as pharmaceutical intermediates. Compliant with GMP and explosion-proof standards, it integrates PLC control and touchscreen operation for real-time monitoring, data recording, and MES connectivity. - Industry-specific configurations, such as

Lithium battery materials: Dust-free filling and metal contamination prevention

Pharmaceutical and chemical sectors: Constructed from 316 stainless steel for easy cleaning and compliance with hygiene standards

Toxic compounds: Negative pressure design with double-sealing barriers to eliminate leakage risk

Applications

Ideal for lithium battery production and pharmaceutical chemical industries where materials require an oxygen- and moisture-free environment. It enables safe handling and packaging of highly active, moisture-sensitive, or toxic compounds while maintaining absolute isolation and product integrity.

Typical Applications

Neodymium-iron-boron (NdFeB) magnetic powder

Neodymium-iron-boron (NdFeB) magnetic powder Lithium cobalt oxide (LiCoO₂) powder

Lithium cobalt oxide (LiCoO₂) powder

Compatible Equipment

This weighing and dispensing isolator can be integrated with our vacuum conveying units to form a complete and enclosed material handling and packaging line, tailored to meet various production requirements.

For powder processing, we also provide a one-stop solution.

How does the weighing and dispensing system ensure uninterrupted production?

How does the weighing and dispensing system ensure uninterrupted production?

It employs a dual-buffer design to maintain continuous operation:

- Inlet buffer chamber allows preloading of 8–12 bottles, functioning like an “ammunition depot” for constant supply.

- Empty bottle storage chamber acts as a “reserve unit,” storing up to 20% backup containers for seamless bottle replacement without process interruption.

How is contamination prevented when handling fine or dusty nanomaterials?

How is contamination prevented when handling fine or dusty nanomaterials?

The containment isolator system incorporates a three-level dust control strategy:

- Vertical auger filling ensures smooth downward discharge, minimizing dust dispersion.

- Inflatable sealing gate limits powder escape to less than 0.01% during operation.

- Gas circulation system performs up to 15 air exchanges per hour within the chamber, maintaining a clean and stable environment.