Powder Handling & Processing Equipment and Systems

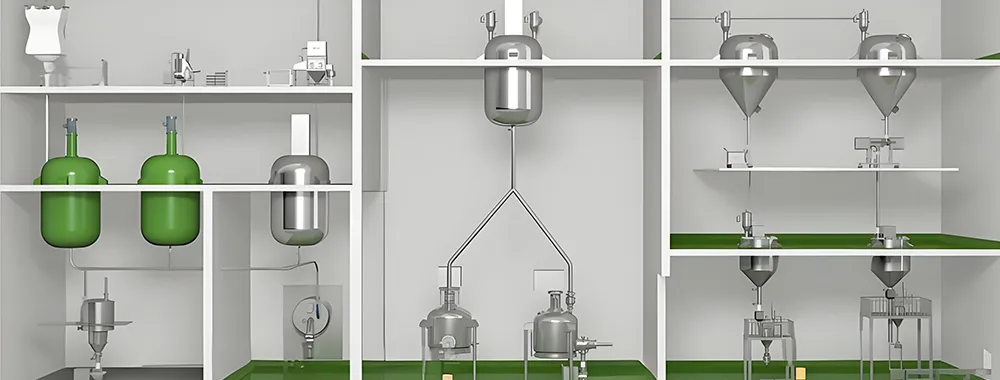

Integrated Powder Handling System (Mixing/Sifting/Filling)

Double cone mixer, rotary centrifugal sifter, vacuum conveying equipment and gravimetric filling machine

This integrated powder handling system is designed for automated, dust-free powder processing from mixing and sifting to conveying and packaging. The material is first homogenized in a double cone mixer, then transferred by Vacuum Conveyor 1 to Silo #1. It passes through a rotary centrifugal sifter to separate material according to specified particle sizes, with qualified powder collected in Silo #2. The screened powder is conveyed again via Vacuum Conveyor 2 to Silo #3, where it is precisely weighed and packaged using a gravimetric filling system.

- Double cone mixer

- Rotary centrifugal sifter

- Vacuum conveying equipment

- Rotary valve gravimetric filling machine

The entire powder handling process is fully enclosed and PLC-controlled, compliant with the latest GMP standards for dust-free and hygienic powder handling environments.

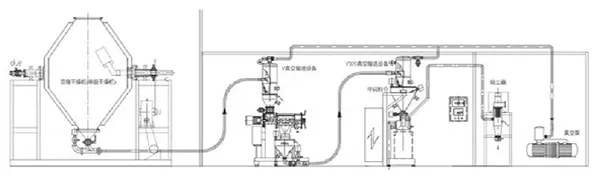

A combined double cone sifting and hammer mill system is available for fine powder processing. This configuration includes a rotary sifting silo integrated with a CFJ-15 hammer mill, enabling continuous, high-efficiency grinding after homogeneous mixing and direct transfer through a closed pipeline.

This integrated powder processing system is ideal for industries requiring precise powder quality control, contamination-free operation, and continuous production efficiency.

For powder processing, we also provide a one-stop solution.

How does the weighing and dispensing system ensure uninterrupted production?

It employs a dual-buffer design to maintain continuous operation:

- Inlet buffer chamber allows preloading of 8–12 bottles, functioning like an “ammunition depot” for constant supply.

- Empty bottle storage chamber acts as a “reserve unit,” storing up to 20% backup containers for seamless bottle replacement without process interruption.

How is contamination prevented when handling fine or dusty nanomaterials?

The containment isolator system incorporates a three-level dust control strategy:

- Vertical auger filling ensures smooth downward discharge, minimizing dust dispersion.

- Inflatable sealing gate limits powder escape to less than 0.01% during operation.

- Gas circulation system performs up to 15 air exchanges per hour within the chamber, maintaining a clean and stable environment.

Can the gravimetric filling system be connected to an existing production line for full automation?

The design of dust-free gravimetric filling machine supports seamless process integration with an existing production line.

- Upstream connection: compatible with vibrating feeding stations, pulverizers, and fluid bed dryers to enable a fully automated “unpacking → grinding → drying → packaging” workflow

- Smart control: centralized PLC system with touchscreen interface for parameter settings, fault diagnostics, and production data recording

- Case example: in an inulin production line, integration of wet granulation, extrusion, drying, and dust-free packaging increased overall production efficiency by 40%