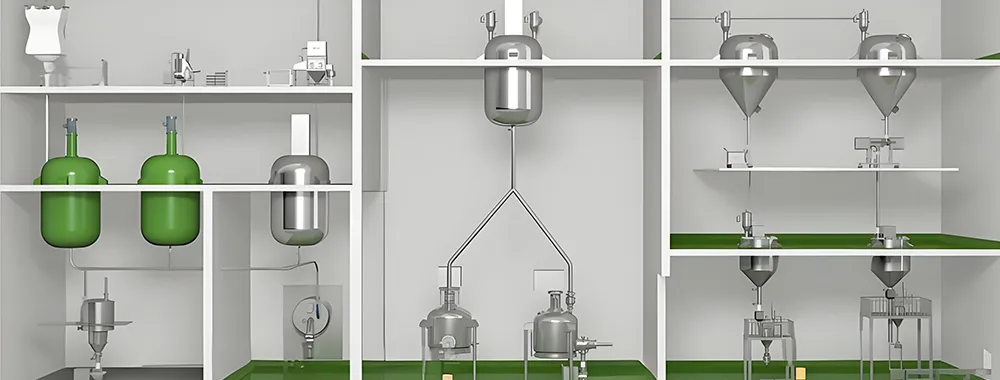

Powder Handling & Processing Equipment and Systems

Weighing & Filling Equipment

Powder weighing and filling systems for precise and dust-free packaging of free-flowing powders and granules

Small Bag Gravimetric Filling Machine (5-100kg)

-

- Gravimetric Filling Machine (with Vertical Auger Filler) Ideal for filling free-flowing powders and granules into 5kg to 60kg bags, this filling machine with vertical auger filler uses a precision servo drive motor to drive the screw shaft, providing faster response, smoother acceleration and deceleration, and higher motion accuracy compared to conventional auger fillers.

- Packaging range

5–60kg - Packaging accuracy

±20g

- Packaging range

-

- Gravimetric Filling Machine (with Horizontal Auger Filler) The servo-driven auger filling system controls the auger shaft through a servo motor.

- Filling accuracy

±100g - Filling speed

25kg/90s - Filling range

10–100kg

- Filling accuracy

-

- Dust-Free Gravimetric Filling Machine (Continuous Liner Type) The dust-free gravimetric filling system consists of a vacuum feeder, buffer hopper, metering valve, dust-free filling head, and weighing unit, along with an integrated dust collection system, isolation barrier, and CIP automatic cleaning module.

- Filling accuracy

±100g - Filling speed

25kg/90s - Filling range

10–100kg

- Filling accuracy

FIBC Filling Machine (100-1000kg)

-

- FIBC/Bulk Bag Filler (Modular Design) The big bag filling machine is engineered for precise and hygienic packaging of powders, granules, and other free-flowing bulk materials into flexible intermediate bulk containers (FIBCs). The modular design allows seamless system integration and customization for various process layouts and production requirements.

- Weighing range

100–300kg /300–500kg /500–1000kg - Accuracy

±0.2%

- Weighing range

Solutions for Industries

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.