Powder Handling & Processing Equipment and Systems

Vertical Double Ribbon Mixer

Industrial powder blending machine for intensive mixing of powders and granules

The vertical double ribbon mixer is designed for efficient, high-precision mixing of powders and granular materials. Its dual-ribbon design enables upward, downward, and inward circulation of materials, achieving fast and uniform mixing even with complex formulations.

Specifications

| Model | Motor power | Rotation speed |

| 11kW | 55rpm | |

| 18.5kW | 50rpm | |

| 22kW | 45–50rpm | |

| Non-standard model | Customizable | Customizable |

Features

- Highly efficient mixing performance

The double-ribbon structure promotes three-dimensional material flow such as lifting, folding, and circulating to ensure rapid and uniform blending of powders and granules. - Dual operation modes for powerful mixing and complete discharge

High-speed rotation provides intensive mixing, while low-speed operation allows nearly residue-free discharge, improving efficiency and reducing material loss. - Low residue and easy cleaning

The conical bottom design facilitates complete material discharge. The small clearance between paddles and the inner wall minimizes residue. Optional CIP (Clean-in-Place) system enables fast, thorough cleaning with recyclable cleaning solution. - Multi-purpose design with optional drying function

The mixer can be upgraded with spray cleaning, hot-air drying, heating, and insulation systems, easily transforming it into an integrated mixing-drying unit for extended process capability. - Suspended bearing design for contamination prevention

The top-mounted agitator shaft keeps bearings isolated from the product area, eliminating lubricant contamination risk, ideal for pharmaceutical and food-grade applications. - Compact structure for efficient space utilization

The vertical conical configuration requires minimal floor space and allows centralized discharge, making it suitable for facilities with limited production areas. - Stable operation and easy maintenance

Equipped with a standardized drive system for smooth, low-noise performance and minimal maintenance requirements, ensuring long-term reliability. - Flexible customization options

Customizable according to capacity, cleaning standards, and heating requirements to meet specific process needs across various industries.

Typical Applications

Soybean powder

Soybean powder Herbal powder

Herbal powder

Compatible Equipment

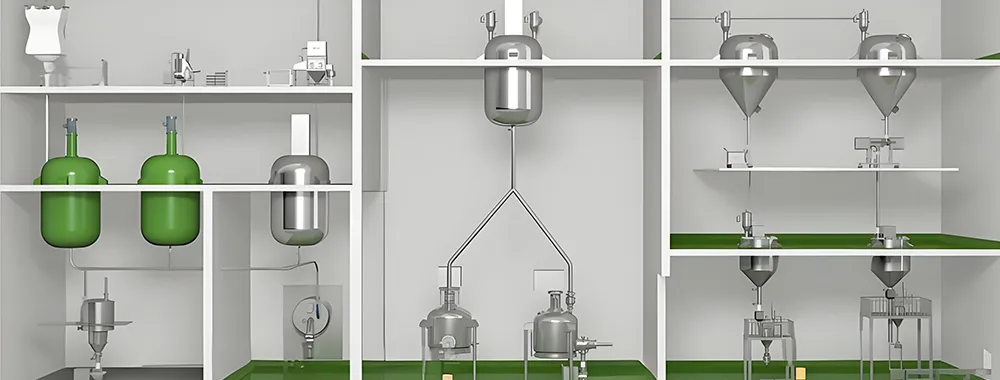

This vertical double ribbon mixer can be integrated with our vacuum conveying system and weighing and packaging systems to form a complete production line solution.

Project Implementation Showcase

Application of multi-level mixing system at a pharmaceutical company

Application of multi-level mixing system at a pharmaceutical company Application of multi-level mixing system at a pharmaceutical company

Application of multi-level mixing system at a pharmaceutical company

For powder processing, we also provide a one-stop solution.

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.