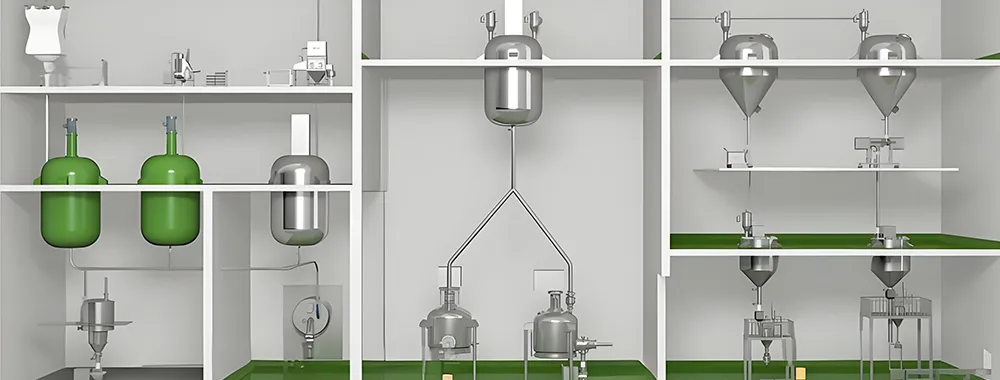

Powder Handling & Processing Equipment and Systems

Big Bag & Sack Discharging Equipment

Big Bag Discharging Stations (FIBC Emptying Stations)

The big bag discharging stations are designed for safe and efficient unloading of powders and bulk solids from FIBC bags. It can be integrated with vacuum conveying equipment and milling systems to create a fully automated and dust-free powder handling process.

-

- Big Bag Discharging Station The big bag discharging station lifts the FIBC to the feed inlet, where the operator manually releases the bag outlet tie and initiates discharge.

- Applicable bag

FIBC bulk bags (tonne bags) - Hoist lifting capacity

0.2-1.5T - Working pressure

0.5-0.6MPa - Operating temperature

-20℃ to 45℃

- Applicable bag

-

- Big Bag Discharging Station (with Pneumatic Massage Units) The discharging system lifts the FIBC bag to the feed inlet, where the operator unties the outlet rope to begin unloading. The built-in pneumatic massage units assist material flow by gently agitating the bag, allowing powder or granular materials to fall by gravity into the buffer hopper.

- Applicable bag

FIBC bulk bags (tonne bags) - Hoist lifting capacity

0.2-1.5T - Working pressure

0.5-0.6MPa - Operating temperature

-20℃ to 45℃

- Applicable bag

Integrated FIBC & Small Bag Discharging System

-

- Integrated FIBC & Small Bag Discharging System The powder unloading system consists of a vibrating-type big bag discharging station, crusher, small bag dump station, dust collection system, pneumatic rotary valve, and U-type screw conveyor. During operation, material from the FIBC is lifted by an electric hoist and unloaded through the vibrating discharging station. Learn more

Containment Discharging Systems

-

- Containment Charging Isolator The containment charging isolator provides a sealed solution for powder discharging and transfer. Material bags are conveyed via roller tracks and passed through a transfer window into the operating chamber.

- Overall dimensions

Customized - Working pressure

-0.7kPa to +0.7kPa - Optional Features

Oxygen concentration control; Nitrogen purging

- Overall dimensions

-

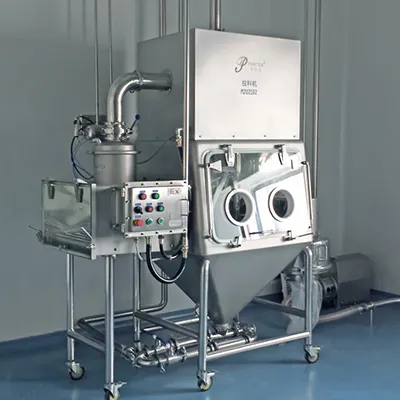

- Containment Glovebox A containment glovebox is designed for the safe handling of potent or hazardous powders and charging of reactors under fully sealed conditions.

- Overall dimensions

Customized - Working pressure

-0.7kPa to +0.7kPa - Optional Features

Oxygen concentration monitoring; Nitrogen purging

- Overall dimensions

-

- Aseptic Glovebox Isolator Designed for aseptic and high-containment operations, aseptic glovebox isolator is suitable for the pharmaceutical and battery industries.

- Overall dimensions

Customized - Working pressure

-0.7kPa to +0.7kPa - Optional features

Oxygen concentration monitoring; Nitrogen purging

- Overall dimensions

Solutions for Industries

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.