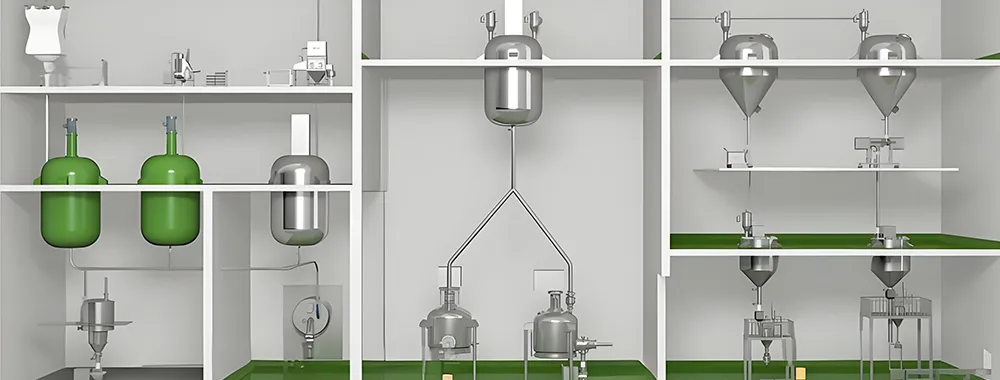

Powder Handling & Processing Equipment and Systems

Big Bag Discharging Station (with Pneumatic Massage Units)

Bulk bag unloading system with pneumatic massage paddles to loosen compacted powders for clog-free discharge

- Applicable bag: FIBC bulk bags (tonne bags)

- Hoist lifting capacity: 0.2-1.5T

- Working pressure: 0.5-0.6MPa

- Operating temperature: -20℃ to 45℃

The discharging system lifts the FIBC bag to the feed inlet, where the operator unties the outlet rope to begin unloading. The built-in pneumatic massage units assist material flow by gently agitating the bag, allowing powder or granular materials to fall by gravity into the buffer hopper. Material is then transferred via a screw conveyor to the next processing step. The fully enclosed structure maintains a clean, dust-free working environment, ideal for pharmaceutical, chemical, and food industries.

Features

- Dust-free operation

Pneumatic massage units effectively loosen compacted materials, ensuring smooth discharge into the hopper. The sealing ring and bag clamping system prevent dust leakage during unloading. - Safe and reliable structure

All contact parts are available in SS304 (food grade) or SS316L stainless steel, providing corrosion resistance and hygiene compliance for pharmaceutical and chemical applications. - Reduced manual handling

The system is equipped with an electric hoist for easy lifting of FIBCs. Bags are secured to a rigid frame, and the hoist travels along a rail to position the bag accurately above the discharge station. After emptying, the clamping device releases the bag, allowing the operator to remove it safely and efficiently.

Typical Applications

Fertilizer

Fertilizer Lactose

Lactose Milk powder

Milk powder

Customizable Options

- Core functional modules

Load capacity: Configurable for FIBC bags ranging from 200 to 1500kg

Equipment dimensions: Adjustable in length, width, and height according to plant layout or space constraints

Material construction: Product contact surfaces available in SS304 (food grade) or SS316L stainless steel for corrosion resistance in pharmaceutical and chemical applications - Adaptation for special conditions

Sealed and eco-friendly design: Fully enclosed structure prevents dust leakage and ensures clean operation

Inert gas protection: Optional nitrogen purging system for flammable, explosive, or oxidation-sensitive materials - Structural and configuration options

Lifting system: Custom electric hoist design supporting 1–3 ton lifting capacity with tailored lifting height

Downstream connectivity: Compatible with silos, screw conveyors, or tubular chain systems; customizable flange interfaces available for seamless integration

For powder processing, we also provide a one-stop solution.

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.