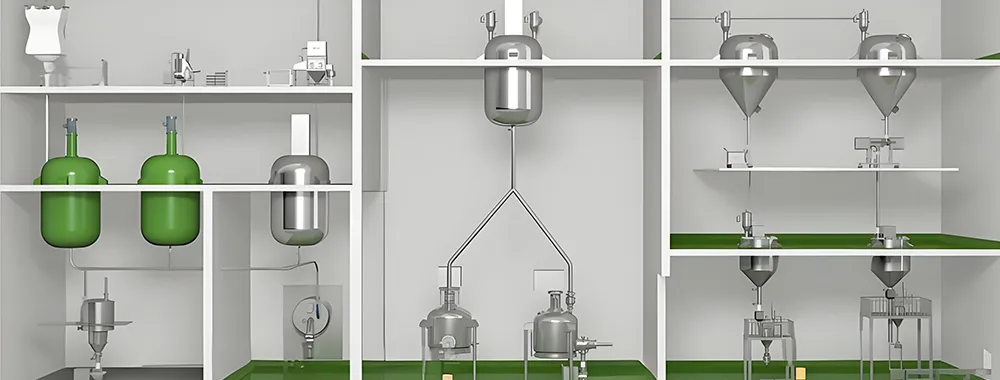

Powder Handling & Processing Equipment and Systems

Aseptic Glovebox Isolator

Multi-chamber powder handling isolator for aseptic handling of highly potent materials in pharmaceutical or battery sectors

- Overall dimensions: Customized

- Working pressure: -0.7kPa to +0.7kPa

- Optional features: Oxygen concentration monitoring

Nitrogen purging

Designed for aseptic and high-containment operations, aseptic glovebox isolator is suitable for the pharmaceutical and battery industries. The multi-chamber powder handling isolator provides a sealed environment for processing highly potent materials while maintaining operator safety and product purity.

Features

- The isolator is designed with modular two chambers (buffer and operation) or multiple chambers (inlet buffer, operation, and outlet buffer), configured according to process requirements.

- Designed to meet high-level containment levels from OEB4 to OEB5, ensuring effective personnel and environmental protection in high-potency applications.

- Equipped with nitrogen purging, filtration, CIP (clean-in-place), air flushing, and drainage interfaces for versatile aseptic operation.

- Utilizes an efficient push-push filter change system for safe and contamination-free maintenance.

- Continuous pressure monitoring and control between the operation chamber, buffer chambers, and external environment, including both sides of the filter.

- For nitrogen-pressure operation, an integrated oxygen concentration sensor and automatic alarm system maintain safe working conditions.

- Constructed with smooth, rounded corners and mirror-polished internal surfaces, eliminating dead zones and ensuring easy cleaning in compliance with aseptic standards.

- Custom configurations available to meet specific process, facility, and spatial requirements.

Applications

Used in the production, discharging, weighing, and packaging processes of lithium battery materials, sterile APIs, biopharmaceuticals, and chemical products.

Typical Applications

Hydroxyapatite powder

For powder processing, we also provide a one-stop solution.

Can the containment discharging isolator help control dust and improve air quality in the workshop?

Can the containment discharging isolator help control dust and improve air quality in the workshop?

The containment discharging isolator operates under a fully enclosed negative-pressure design, preventing powder leakage during discharging. Combined with a high-efficiency dust collector, dust emission is effectively minimized, maintaining a clean and compliant working environment.

Can the equipment be integrated with existing production lines?

Can the equipment be integrated with existing production lines?

The isolator features flexible dimensional and interface customization. A compact version with a total height of approximately 1.8 m (including hopper) is available for low-ceiling workshops. Multiple interface options such as flange and quick-clamp fittings allow seamless connection with silos, vacuum conveyors, or big bag discharging frames. Material samples can also be tested in advance to evaluate flowability and system compatibility.