Powder Handling & Processing Equipment and Systems

IBC Bin (Hopper Storage Bin)

Mobile storage hopper for handling, storing, and transferring powder materials in a closed manner

The IBC bin (intermediate bulk container) is developed based on advanced European pharmaceutical handling technologies, designed for the enclosed transfer of powder materials in pharmaceutical production. Equipped with silicone sealing rings on both the top cover and discharge valve, the hopper storage bin ensures airtight, moisture-proof, and contamination-free material storage.

Materials can be blended, stored, and transferred within the same container, minimizing manual handling steps such as refilling or transferring and effectively preventing cross-contamination. The system fully complies with GMP requirements for pharmaceutical manufacturing.

Specifications

| Model | Capacity | A | B | C | D | H | H1 | H2 | H3 | H4 | Weight |

| 200L | 800 | 430 | 250 | 60° | 970 | 54 | 100 | 740 | 160 | 120kg | |

| 300 L | 800 | 430 | 250 | 60° | 1120 | 54 | 250 | 740 | 160 | 140kg | |

| 400 L | 800 | 430 | 250 | 60° | 1270 | 54 | 400 | 740 | 160 | 160kg | |

| 500 L | 1000 | 430 | 250 | 60° | 1270 | 52 | 200 | 644 | 158 | 190kg | |

| 600 L | 1000 | 430 | 250 | 60° | 1370 | 52 | 300 | 644 | 158 | 220kg | |

| 800 L | 1000 | 430 | 250 | 60° | 1570 | 52 | 500 | 644 | 158 | 260kg | |

| 1000 L | 1200 | 560 | 300 | 70° | 1540 | 78 | 420 | 643 | 203 | 300kg | |

| 1200 L | 1200 | 560 | 300 | 70° | 1680 | 78 | 560 | 643 | 203 | 330kg | |

| 1500 L | 1200 | 560 | 300 | 70° | 1890 | 78 | 770 | 643 | 203 | 390kg | |

| 1800 L | 1200 | 560 | 300 | 70° | 2100 | 78 | 980 | 643 | 203 | 450kg | |

| 2000 L | 1200 | 560 | 300 | 70° | 2240 | 78 | 1120 | 643 | 203 | 520kg |

Features

- Constructed from high-quality austenitic stainless steel (304 or 316L).

- The square-rounded conical hopper design ensures smooth transitions with no dead corners or residue, providing a clean and elegant appearance.

- Both internal and external surfaces are highly polished, achieving internal surface roughness of Ra≤0.2 μm and external surface roughness of Ra≤0.4 μm.

- Custom-designed top cover and butterfly valve with silicone seals ensure airtight closure.

- All welded joints are beveled and welded on both sides using argon arc welding, then ground and polished; welding quality conforms to JB4708 and JB4709 standards.

- Equipped with specially designed casters that protect cleanroom floors without leaving marks.

- The hopper bin offers excellent structural strength and deformation resistance.

Typical Applications

Microcrystalline cellulose

Microcrystalline cellulose Lithium cobalt oxide

Lithium cobalt oxide Probiotic powder

Probiotic powder

Project Implementation Showcase

Used for temporary pharmaceutical storage at a pharmaceutical company

Used for temporary pharmaceutical storage at a pharmaceutical company Used for material transfer at a pharmaceutical company

Used for material transfer at a pharmaceutical company Used for intermediate pharmaceutical storage at a pharmaceutical company

Used for intermediate pharmaceutical storage at a pharmaceutical company

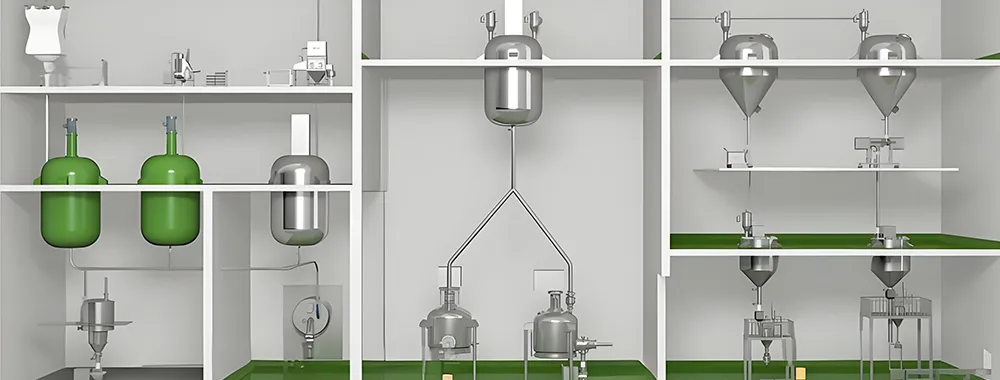

For powder processing, we also provide a one-stop solution.

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.