Powder Handling & Processing Equipment and Systems

FIBC/Bulk Bag Filler

Big bag filling machine with modular design for weighing and filling of big bags (FIBCs) with powders, granules or other free-flowing materials

- Weighing range: 100–300kg /300–500kg /500–1000kg

- Accuracy: ±0.2%

- Feeding configurations: Screw feeder, combination valve, positioning valve, rotary valve, vibrating chute or pipe

The big bag filling machine is engineered for precise and hygienic packaging of powders, granules, and other free-flowing bulk materials into flexible intermediate bulk containers (FIBCs). The modular design allows seamless system integration and customization for various process layouts and production requirements.

Features

- Designed for high-precision filling of 100–1000kg bulk bags, ideal for industries with strict hygiene and process control requirements

- Integrated weighing module within the machine frame ensures stable load-cell accuracy by eliminating interference from floor vibrations

- High-precision electronic weighing system with a measurement error of less than ±0.2%, meeting demanding process specifications

- Multiple feeding configurations available such as screw feeder, rotary valve, butterfly valve, positioning valve, vibrating chute, or pipe feeding, making the filling system adaptable to different material properties

- Strong modular compatibility: can be integrated with conveying, crushing, screening, dust collection, and metal detection systems to form a complete production line

- Compact, space-efficient structure suitable for cleanroom environments and automated production setups

- Dust-free filling design maintains a clean working area, compliant with GMP and FDA hygiene standards

- Extensive customization capabilities to accommodate various industries, bag types, and process integration needs

Typical Applications

Mineral powder

Mineral powder PE plastic granules

PE plastic granules Feed additives

Feed additives

Customizable Options

- Weighing range

Adjustable from 100kg to 1000kg to suit different FIBC bag sizes and production capacities - Accuracy

Standard precision of ±0.2%; optional high-precision version of ±0.1%, suitable for high-value materials such as lithium battery powders - Feeding options

Available with screw feeder, rotary valve, butterfly valve, vibration chute, or pipe feeding, selected according to material characteristics - Anti-clogging design

Equipped with pneumatic arch breaker or mechanical agitator to prevent bridging and ensure stable flow, especially for cohesive materials - Dust control system

Pulse-jet dust collector for high-dust environments (chemical or construction materials) or negative-pressure sealed suction system for pharmaceutical and food-grade applications - Bag compatibility

Compatible with round, square, antistatic, and food-grade FIBCs - Bag handling options

Manual bag hanging (economic version) or automated clamping and robotic bag handling (for full automation lines) - Filling nozzle design

Standard filling spout for general applications or telescopic filling nozzle to minimize dust emission

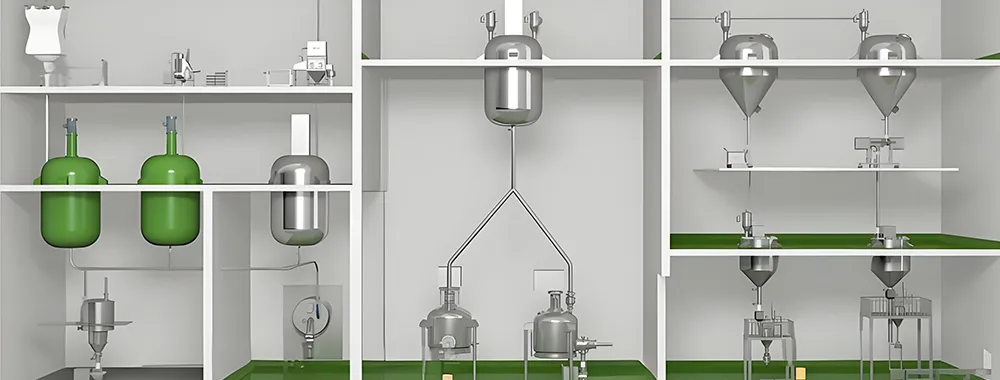

For powder processing, we also provide a one-stop solution.

Which industries is the FIBC filling machine suitable for?

Which industries is the FIBC filling machine suitable for?

FIBC filling machine is widely used in the chemical, building materials, grain, mining, new energy, and recycling industries. The bulk filling system is ideal for large-volume packaging of materials such as fertilizers, cement, feed, mineral powder, and plastic granules.

What level of weighing accuracy can be achieved?

What level of weighing accuracy can be achieved?

The bulk filling machine uses high-precision load cells to ensure stable measurement accuracy. The standard model offers ±0.2% accuracy, while the high-precision version achieves ±0.1%, meeting the requirements for fine or high-value materials.

How fast is the filling process?

How fast is the filling process?

Depending on the material flow and configuration, a single unit can fill between 2–6 tons per hour. When integrated with automated conveying and palletizing systems, total throughput can be significantly increased.

Can the FIBC filling machine be connected to other production line equipment?

Can the FIBC filling machine be connected to other production line equipment?

The FIBC filling system can be linked via PLC or RS485 interfaces to conveyors, palletizing robots, AGV trolleys, or MES systems, forming a fully automated, intelligent bulk packaging line.