Powder Handling & Processing Equipment and Systems

Dust-Free Gravimetric Filling Machine

Gravimetric powder filling system with continuous liners for packaging of toxic or sensitive materials into drums

- Filling accuracy: ±100g

- Filling speed: 25kg/90s

- Filling range: 10–100kg

The dust-free gravimetric filling system consists of a vacuum feeder, buffer hopper, metering valve, dust-free filling head, and weighing unit, along with an integrated dust collection system, isolation barrier, and CIP automatic cleaning module. It enables fully enclosed, dust-free, and sterile operations under automated PLC control, making it suitable for the weighing and filling of toxic, hazardous, or highly active materials. This system is purpose-built for environments that require safe, precise, and contamination-free packaging of high-purity pharmaceutical ingredients, specialty chemicals, and active compounds under stringent handling standards.

- Ensures dust-free and sterile filling operations

- Automated control through a PLC system

- Designed in compliance with GMP standards, supporting in-place cleaning and drying

Industrial-grade glucose

Industrial-grade glucose Inulin

Inulin

- Packaging specification customization

Compatible with 10–100kg standard paper or plastic bags

Adjustable bag opening diameter: 300–800mm

Available in two configurations: low-speed precision filling for pharmaceutical powders or high-speed filling for production line requirements - Safety and protection customization

Inert atmosphere control: nitrogen purging system with ≤0.5% oxygen inside the bag

Explosion-proof certification: compliant with ATEX standards

Fully enclosed design: air cushion sealing with ≤0.1% dust leakage rate

Optional isolation chamber: enables fully contained operation for toxic or hazardous materials - Functional module customization

Filling assistance: compatible with roll-type or heat-sealing machines

Material handling optimization: pneumatic butterfly valve with vibration motor to prevent bridging and clogging

Iron removal and dust control module: integrated magnetic separator with negative-pressure back-suction system

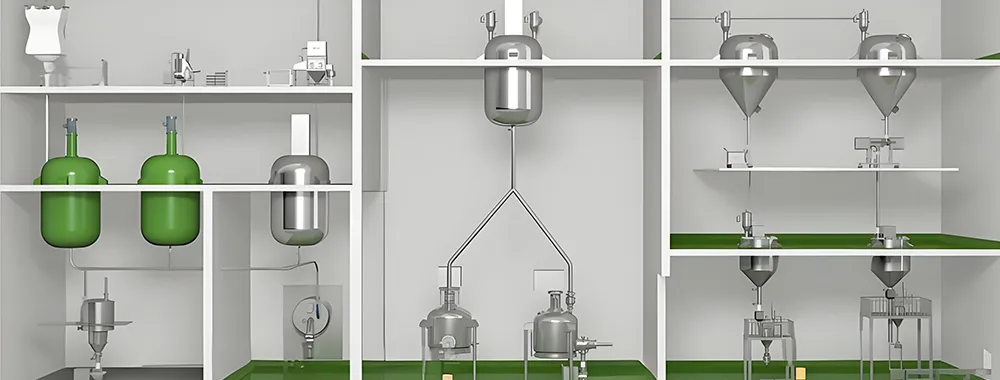

This dust-free gravimetric filling system can be integrated with our pulverizer, sifter, and fluid bed dryer to form a complete production line, meeting various customer requirements.

For powder processing, we also provide a one-stop solution.

How does the filling system ensure a high level of cleanliness? Can it meet GMP cleanroom requirements?

How does the dust-free filling system prevent clogging when handling viscous or poorly flowing materials?

Can the gravimetric filling system be connected to an existing production line for full automation?

The design of dust-free gravimetric filling machine supports seamless process integration with an existing production line.

- Upstream connection: compatible with vibrating feeding stations, pulverizers, and fluid bed dryers to enable a fully automated “unpacking → grinding → drying → packaging” workflow

- Smart control: centralized PLC system with touchscreen interface for parameter settings, fault diagnostics, and production data recording

- Case example: in an inulin production line, integration of wet granulation, extrusion, drying, and dust-free packaging increased overall production efficiency by 40%