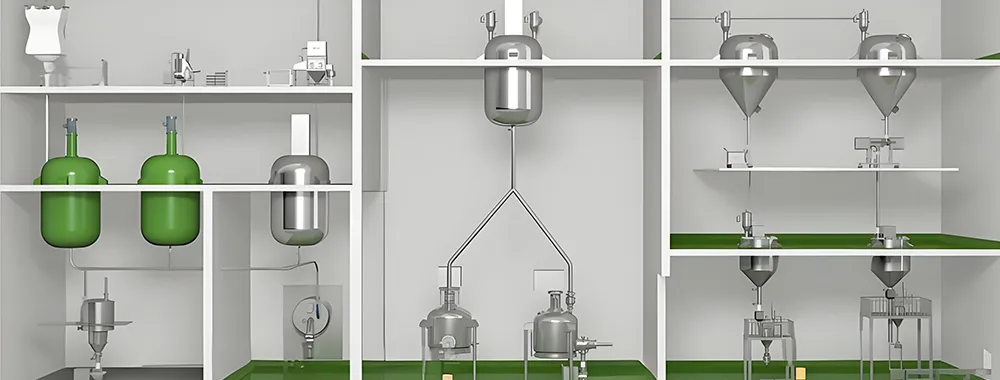

Powder Handling & Processing Equipment and Systems

Sifting Equipment

Powder sieving machines for separation and classification of bulk solids

-

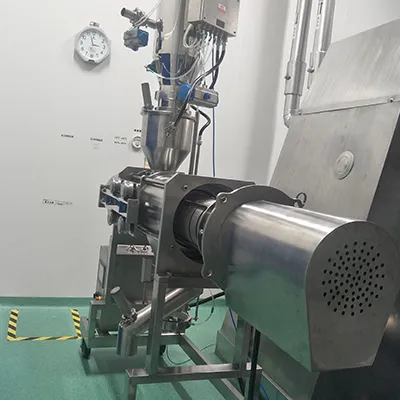

- Rotary Centrifugal Sifter (Single Shaft) The rotary centrifugal sifter is designed for precise separation and sieving of powders and granules through the action of centrifugal force. Material is fed into the rotating chamber via a screw conveyor, where high-speed rotating blades efficiently classify and screen particles.

- Processing capacity

200kg/h - Rotation speed

1500rpm - Power

1.1kW - Net weight

250kg

- Processing capacity

-

- Rotary Centrifugal Sifter (Twin Shaft) The twin-shaft rotary centrifugal sifter features a dual-motor system, independently controlling the feed screw and sifting chamber. Material is conveyed by the screw into the rotating chamber, where high-speed blades perform efficient sieving and filtration.

- Processing capacity

1000kg/h - Rotation speed

1500rpm - Power

3.0kW - Net weight

340kg

- Processing capacity

Solutions for Industries

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

The powder processing and palletizing equipment is widely used in pharmaceutical, food, and chemical applications. Selection can be made based on material type (e.g. wet, dry, or fragile), flowability, and target throughput. Based on these parameters, a suitable model and configuration are recommended for the intended process.

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Our powder handling equipment can be built using high-temperature-resistant, corrosion-resistant, and explosion-proof designs. Typical options include 316L stainless steel construction, PTFE sealing, explosion-proof motors, and nitrogen inerting systems.

Does the equipment comply with GMP requirements?

Does the equipment comply with GMP requirements?

Our powder processing machines are designed in line with GMP requirements. Product-contact surfaces can be supplied in SS304 or SS316L with polished finishes down to Ra ≤ 0.4 μm, suitable for installation in clean production areas.

Can the production line be customized to match specific output targets and plant layout constraints?

Can the production line be customized to match specific output targets and plant layout constraints?

Complete lines can be tailored, including equipment footprint, capacity range, and inlet/outlet height, to achieve direct integration into existing processes.

Can electrical specifications and control systems match local standards in different countries?

Can electrical specifications and control systems match local standards in different countries?

Voltage and frequency can be supplied according to regional standards (for example 220 V / 380 V / 415 V, 50 Hz / 60 Hz). Control systems can include PLC and HMI with Siemens or Schneider electrical components.